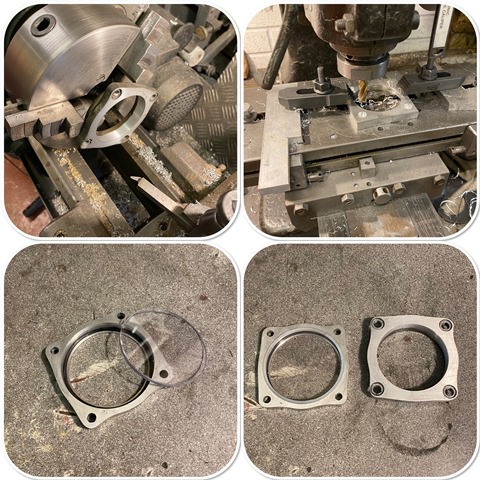

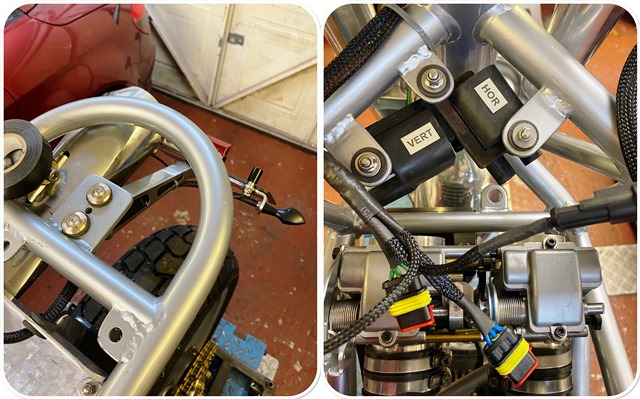

Interesting little mod. The window on the bevels was on the vertical bevel box to check that oil was arriving, as it takes about 30 seconds to reach the top apparently. Unnecessary on the horizontal one, as that gets it's oil first and besides the rev-counter drive is taken from there anyway.

Difficult to see the vertical covers on a belter I guess, but fun to have it on the horizontal I suppose.

Good to see from the video that it only takes about 4 seconds for the oil to reach the top valves.

Did you use a bit of float glass or is it something more exotic?

I remember a circle cutting demo when I worked at a place with resident glazers. Both cutting a disc like yours and also cutting a circular hole in a pane for an extractor or whatever.. If you can do that you know you can cut glass!..

where I stole the idea from

where I stole the idea from

Linear Mode

Linear Mode