I am afraid I am going to have to revive this thread.

On a particularly wet and dirty few hours on the bike, 2000 M900Sie, I thought I could hear a slight noise from the front brakes taking off from a standstill so I decided to give the brakes, F&R, a thorough clean, usual, off with callipers, pads out and into them with a toothbrush and brake cleaner, refitted and bled fronts no problem, discs ok too.

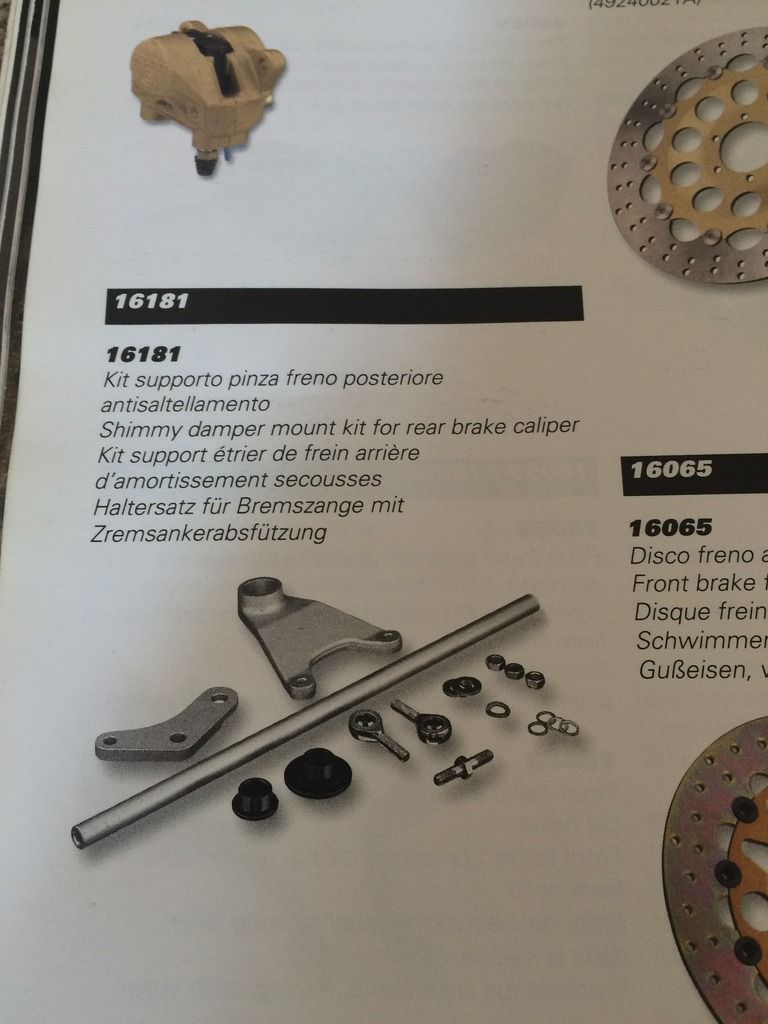

When I moved onto the rear, the wheel was very reluctant to turn backwards like Mr Gazza's. The calliper seems to be the floating type with the torque arm like the one in Flip's post , No.18 in this thread.

I removed the calliper to give it a clean and noticed the front and rear edges just before the pads on the outside half of the calliper, (the side furthest from the wheel), look as though they have been scored, see pic, possibly touching the disc, the disc looks fine and is 4.1 mm thick, so plenty meat on it.

I did notice, however, that the calliper mounting bracket could be moved on the spindle a bit, so I took it off and held it in a vice and with the bushes in I could get a .5mm feeler gauge between the top hat bush and the bracket when moving the bracket.

I take it that there should be NO movement between the bushes and bracket and they should be a snug fit?, if this is the case I would imagine it is possible that this movement caused the scoring on the calliper and I need to get a new set of bushes?

The parts book for a 2000 M900Sie lists another rear brake set up, but '98 900SS F.E. looks the same, can anyone tell me if I'm on the right track and enlighten me on the parts I may need?

Cheers

Roast Beef Monster!

Roast Beef Monster!

Linear Mode

Linear Mode