The odd thing about this is that 40 odd years ago, I had the same thing happen on a Ducati 250 Scrambler. Started 'weaving' a little from the rear and when I looked the swingarm spindle had come out of (the same) side.

On that nothing was actually broken but the pinch bolts wouldn't pinch enough to be secure so I stuck a length of threaded rod/washers/nuts through it to stop it sliding out but I was less finnicky back then!

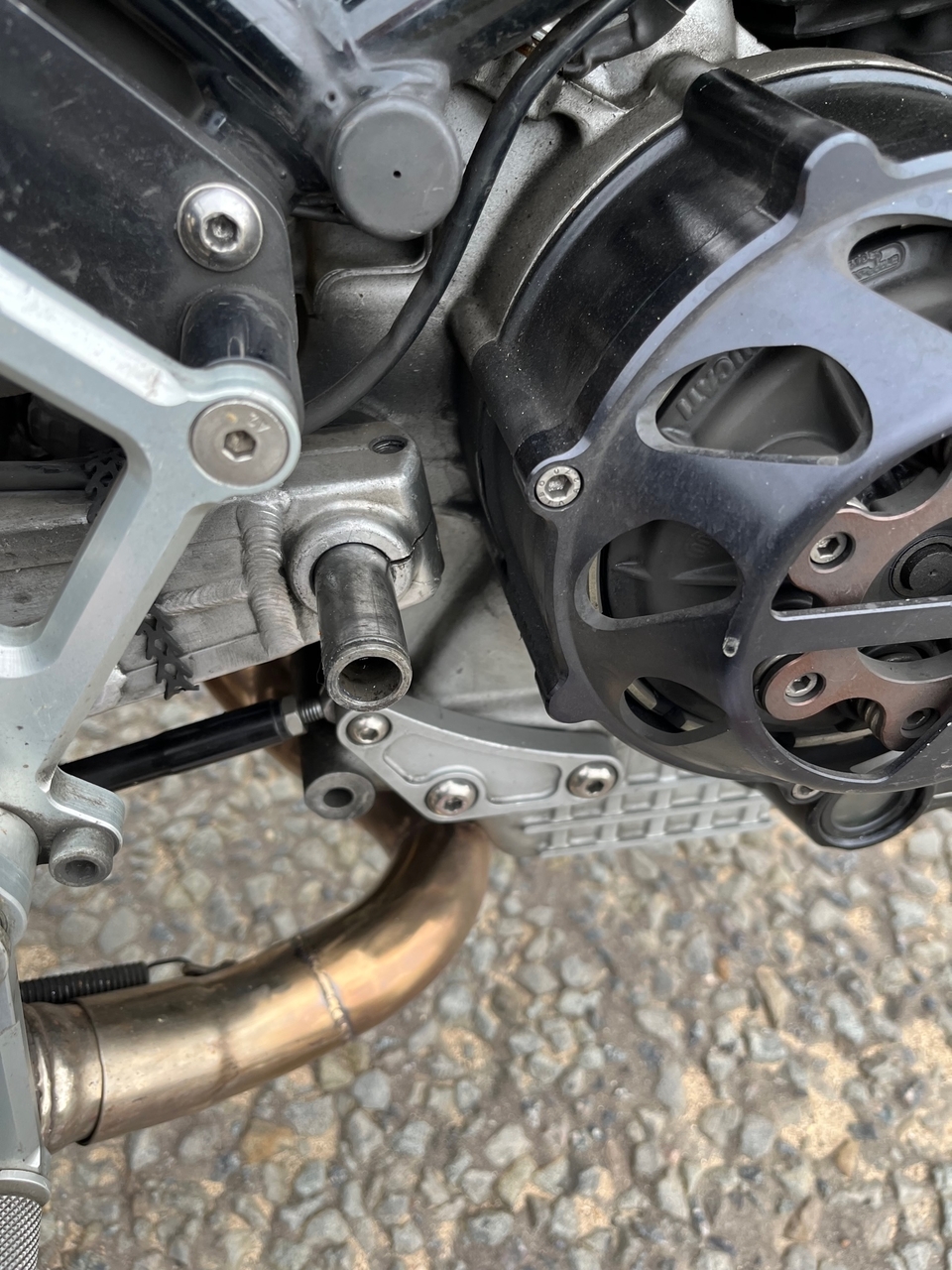

Inspecting everything, I can't find any further damage - the engine cases are fine, as appear to be the bearings but the spindle had pulled back out of the left side of the swingarm, meaning the wobble was due to that side not being attached to anything (single-sided swingarm eat your heart out) and, under throttle the chain would flex the rear end some.

The other arm actually has a little more 'meat' around the boltholes, presumably because it is a later Monster version and they had solved (or at least improved) the problem. So that, and the fact that any repair would be complex and likely doomed to failure means I'll be going with that.

As for the bracing, as mentioned I doubt it really does much, I just bought that arm because it was available when I was looking and it was a nice bit of bling but I have had a few issues caused by the bracing - it makes a very narrow passage for the chain and there is a tendency for the chain to 'bounce' between brace and tyre edge (especially when I tried a 180 tyre) so, not too fussed about it and it does add weight which is not good.

So, onwards and upwards and (hopefully) back together before the weekend to get a bit more riding done during the decent weather.

I've already got 1 bike off the road (916 has leaky fork seals) so I'd like to keep my options open.

Oddly, yesterday whilst riding and before I was aware of this, I was contemplating that if I could only keep 1 bike, it would be the Monster because since I've had it it has been used far more than the other 2 but, at the same time it's been off the road more for various, major repairs.

It's saying something when a 25yr old 916 and a 44yr old Guzzi have been more reliable...

Linear Mode

Linear Mode