Quote:

Originally Posted by slob

Have a play with Autodesk’s Fusion360, if it’s still free for students and hobbyists, easy to use, plenty of how tos on youtube, works on pc or mac.

|

thanks, I will have a play...

The seat pad came back from Aldridge trimming and as usual Karen did a fantastic job… she said she was not asked for orange stitching very often! next job was to make the fuel filter holder… this took some thinking about due to the position, and the fact I wanted it to be secure… In the end I machined a clip out of nylon. there is an annular grove which stops the filter moving, its very secure

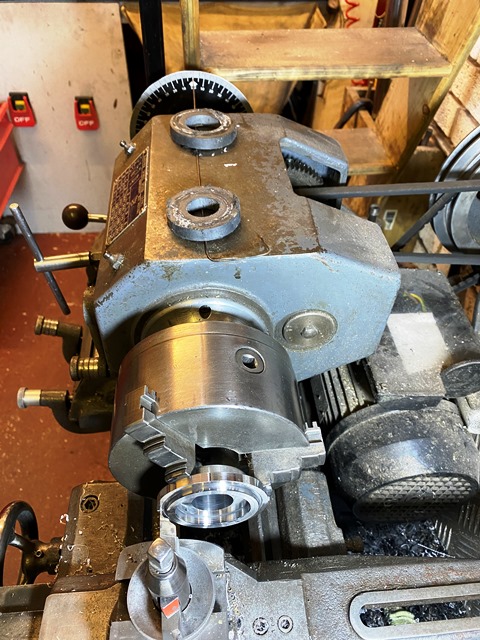

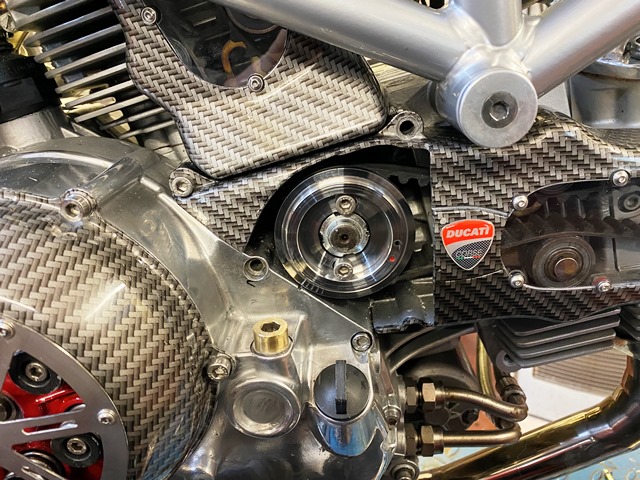

started it up yesterday… it actually started first time!… but it didn’t run well… A quick check on the timing revealed it was significantly out. Looks like I made a calculation error in placing the magnets. rather than re-make the timing wheel, I slotted the mounting holes on the miller. A simple job, but it took ages to set it up! This of course meant that I had to turn off the original timing marks and scribe some new ones. I used a pointer and timing disc in the lathe to do this. the marks were scribed using a sharp tool, drawn across the surface with the cross slide. I think that way they are pretty accurate! here is a short video of it running.

https://www.youtube.com/watch?v=iy-3sPlFi-A

https://www.youtube.com/watch?v=iy-3sPlFi-A