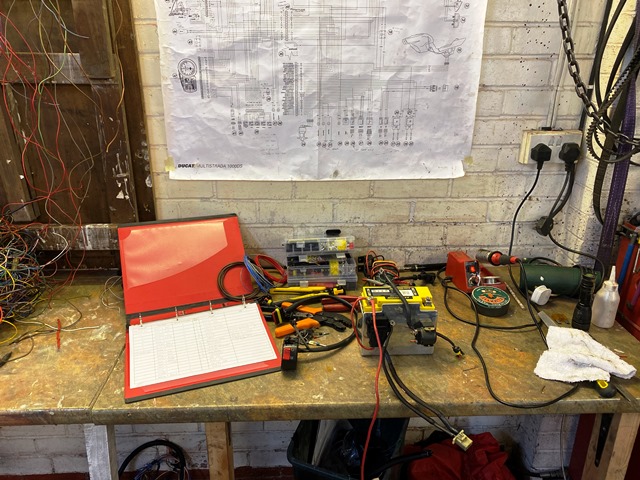

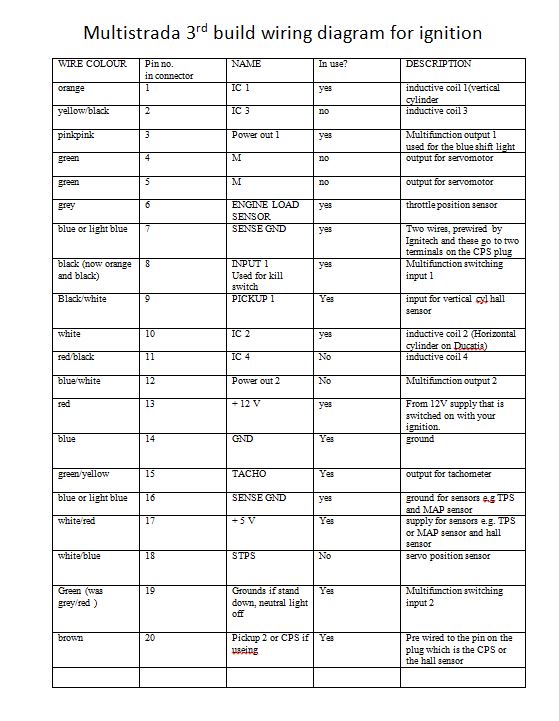

Now for the part I actually enjoy doing… the wiring! I am building this loom completely from scratch, save for things like the handlebar switches, although I am replacing the outer sheathing as it was tatty. I know this is something a lot of people struggle with but over the years I have developed a system… I start with a design in my head and I put it down in rough on my Ipad, using an Ipencil which I find brilliant. then I transfer it to visio, which I print out and add the colour of wires on as I go along. I don’t try to it all on one diagram like in workshop manuals, but keep separate pages for different circuits like lights, indicators, ignition… I also create tables of key components where they have pin outs.

All this is put into the build folder which I always pass on when I sell the bikes.

I have a nice crimp tool which is normally sufficient, but if I am in any doubt I put a dab of solder on the joint. I also don’t use pre insulate connectors, instead I put 20mm of heat shrink on which makes a nice joint, and the heat shrink also supports the joint. If you use the glue lined heat shrink, it also makes the joint waterproof. this is of course if I am not using super seal connectors which are not only excellent, but also cheap! and finally, I use the most useful little kit, which has tools for removing all types of pins from connectors!