5. Swapping Out Valve Seals.

1. Follow the steps above as far as removing the closer shim, clamp the top of the valve so it doesn’t fall and remove the old seal like this:

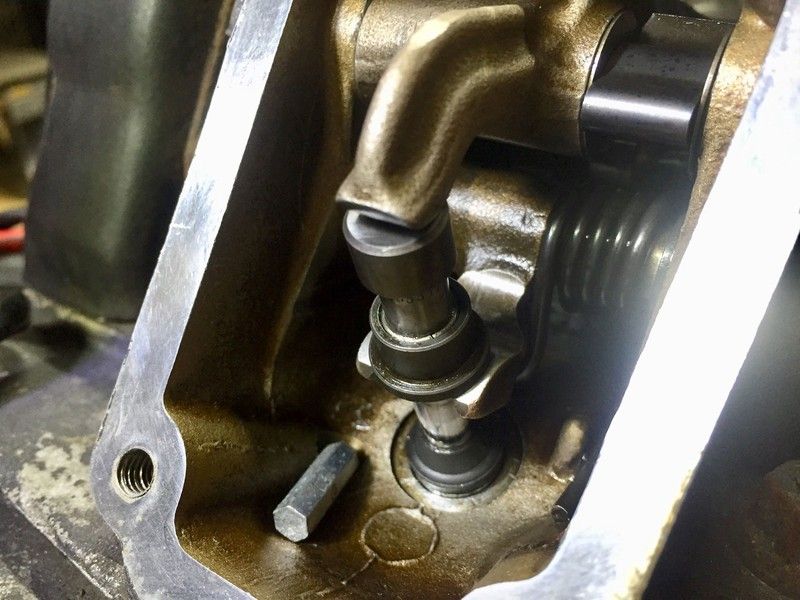

2. You will see from the pic below that there is not enough space around the valve to slide the seal past the rocker. I tried to stretch and manipulate one as well as trying to lower the rocker arm to increase the gap but ended up nicking a chunk out of the seal. Again, another method that required more hands than I had to press the rocker down and safely manipulate the seal without causing damage. With the clearance I achieved the gap was still too tight… you may fare better.

3. The option I went with was to move past TDC just enough to sit the valve on the piston but still have the tip of the stem showing enough to fit the new seal. The picture below shows how far I went to lower the piston but still see the valve and it was approximately two teeth on the pulley of travel.

4. With the valve safely lowered there is just enough clearance to slip the seal over the top.

5. You will notice in the picture above that the new seal has been turned inside out. Several people online recommended this method. Turn the seal inside out, slide the seal onto the valve upside down and then when it touches the valve guide roll the seal over itself from top to bottom. As the seal flips the right way it should seat in the groove around the guide… I tried it this way and didn’t get on with it. The rubber is pretty rigid and doesn’t like being manipulated too much. It eventually flipped but didn’t go over the guide, so it was back to square one. Again, you may get on with it better than me but I went a different way about it.

6. I took the new seal and warmed it up by running it between my fingers so it was slightly more flexible and then put some fresh oil inside and on the valve stem. I then used an allen key in the top of the seal with the tip wedged in the groove that slips over the valve guide and slid them both over the top of the valve. I didn’t get to take a picture as I did it but mocked this up after to show what I mean.

7. From here I ran the allen key around the edge of the seal and lifted it over the guide as it went. As the first part pops over hold it in place with your finger as it will try to pop off as you move around. Use your thumb and forefinger to give it a quick massage after to ensure that it is fully seated all around.

8. Slide the valve up enough to re-clamp it and then rebuild as above with your fresh new seals.