4. My multitasking skills werenít up to scratch to take pics for the next part so youíll have to make do with an alternate pic. With your valve secured and cams moved away from the TDC point you are ready to press the closer rocker down and slide the closer shim down the valve stem exposing the collets. Working out how far to move the cams/pulley was a lot easier with the head off as you can twist it until it stops on its own just before the opposite valve would be about to open. When doing it with the back wheel itís a bit more of a guessing game as to how far youíve gone. With the collets exposed a magnet will easily whip them out safely and reduce your chances of dropping them down the oil drainÖ you did plug that up right??

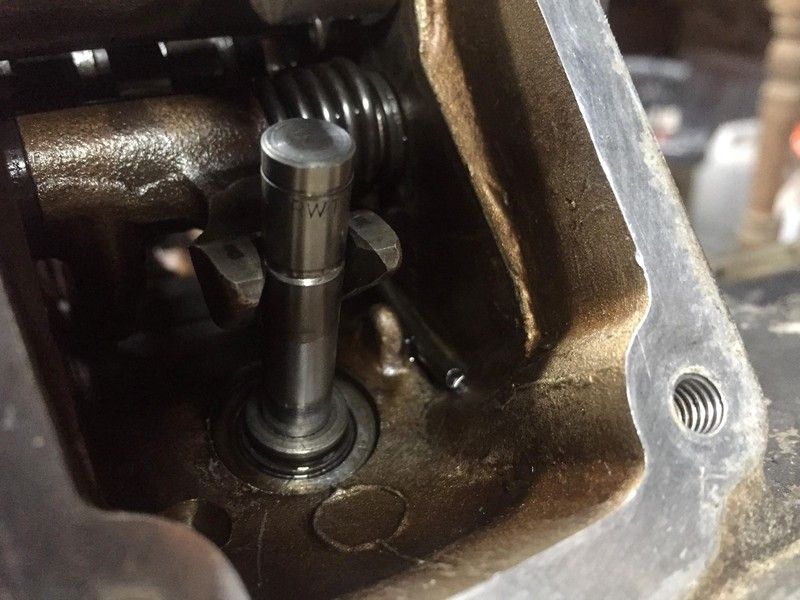

The image below shows the shim and collet removed but you can see that itís a pretty big groove that youíre looking to completely expose so youíll definitely know when the shim has moved out of the way enough. The face of the rocker either side of the groove can be pushed all the way to the bottom leaving plenty of room to remove the collets but the problem you will have is not having enough hands!! The difficulty comes with pressing the rocker down without slipping, sliding the shim down without moving the valve down, grabbing the magnet to get the collets out and also moving the collets around the groove if you cant get to the one at the back. Go slow, have patience. Donít put a screwdriver on the shim, itís bad enough using one on the back of the rocker, the lip is small and will be guaranteed to slip off and damage something like your valve stem seal or worse your hand (done it, not as fun as it sounds)!!

With the collets removed the shim can be slid up and off of the valve. For peace of mind at this point spin your wheel so the cylinder is back to TDC. In the event that something disturbs your zip ties or calipers you wonít lose the valve into the cylinder. Iíd recommend doing them one by one so you donít accidentally mix up parts as they are measured and refit.

Refitting.

Refitting.

1. Once your new shims arrive then refitting is the opposite of the removal process. But are a couple of points to note:

a. Collets Ė indentation. If you are reusing your collets then you will notice that over time a groove has been made into the inside of the collets one side. When refitting this should be on the top side of the collets as it was caused from being repeatedly pressed against the corner of the valves groove by the rocker and the shim. The picture below shows the groove worn into the top on the left collet and the round bottom on the right collet. Unfortunately zoomed arenít the greatest quality ut hopefully it still works for you.

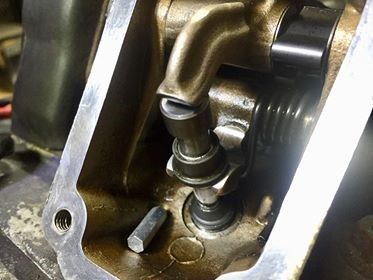

b. When the opener rocker is slid back into place, over the opener shim, ensure that a metal washer sits either side of the gap before refitting the black retaining clip. On the picture below, you can just make them out either side of the fitted clip.

c. Finally, remember to remove what ever you used to block the oil drains!!!