3. Removing Shims.

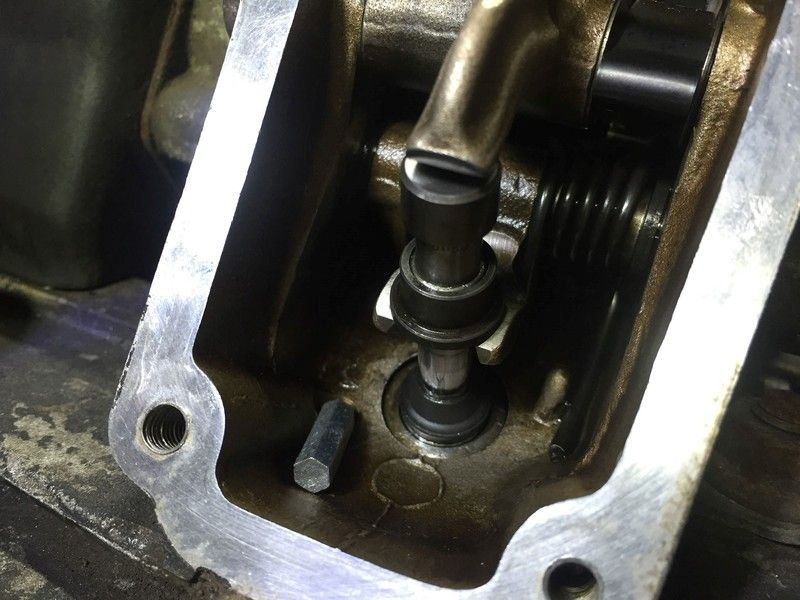

1. To adjust the clearances, you need to remove the old shims and measure them to calculate the new sizes. First up block the oil drain in the bottom left of the picture with an allen key or an ear plug to stop anything that you’re working on dropping down. Then pry the black retaining clip in the top right off. Be careful as these can go flying across the room.

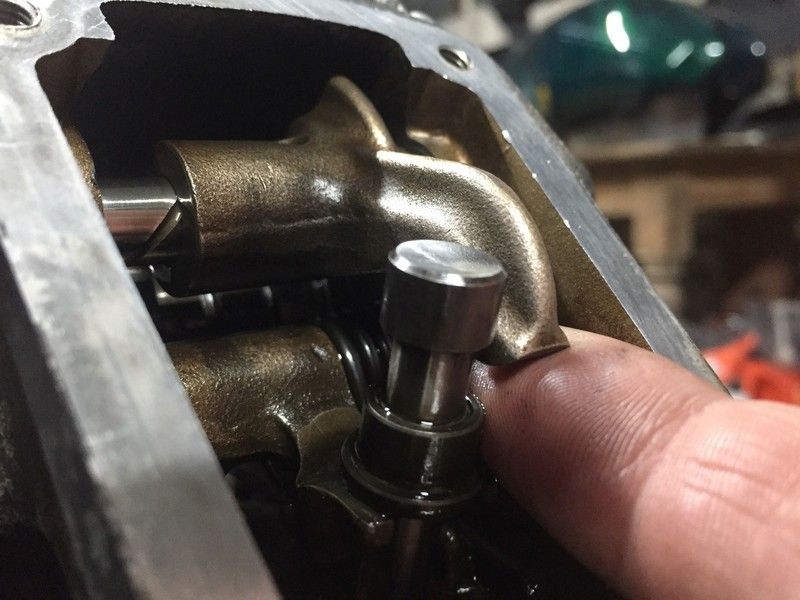

2. With the retaining clip removed the opener rocker arm can be slid to the side. I found that to do this I had press the closer rocker and valve down out of the way. To press the closer and valve down further I had to move the cam pulley to just before or just after TDC depending on which valve I was working on. With the valve out of the way the opener rocker can drop slightly and move to the side exposing the opener shim. The opener shim can now be pulled off from the valve.

3. To remove the closer shim the closer rocker needs to be pressed all the way down so that the closer shim can be slid down the valve and the retaining collets can be removed. To press the closer rocker down the cams must be rotated to before or after TDC. But BEWARE, once the collets are removed there is nothing to stop the valve falling into the cylinder. One method I heard to prevent this was to fill the cylinder/head with rope through the spark plug hole, another was to use a long zip tie around the stem and weight the end of the tie with mole grips so the weight stops it falling and a third way that I read was to use forceps to grip the valve. I had a go with all three.

a. The rope worked but I was always wary that I hadn’t filled it enough, that as I worked the rope may shift and that I may be leaving debris in the cylinder. When you turn the engine back to TDC to compress the rope against the head it may compress and move too far so you cant depress the rocker as far as you need to remove the collets. So it’s a balancing act.

b. If you zip tie the top of the valve to remove the collets you then need to use another zip tie at the base before cutting the first off to remove the shim. If you just go for zip tying the base it may get in the way of the rocker depending on the size of the ties that you have. You also need to ensure that they are ratcheted right up as the valve can slip through the loop if you’re not careful, or put a slim piece of electrical/self amalgamating tape around the valve for the tie to bed into. That should help with slipping. Instead of mole grips as weight I also tried attaching the zip tie to the opposite rocker, with another zip tie, to hold the valve up.

c. I ended up going with the forceps method but it isn’t without flaws. I used two sets in the same places the zip ties were tried and they are quick and easy to switch between the two but they can be slippery so you need to double check they are locked and gripping before removing the second set. I wrapped self amalgamating tape around the tips and also cut half of the loop tip off to make them smaller to work around. If I was feeling paranoid about how well one was ripping I used a Velcro tie around the ratchet to stop it popping open.