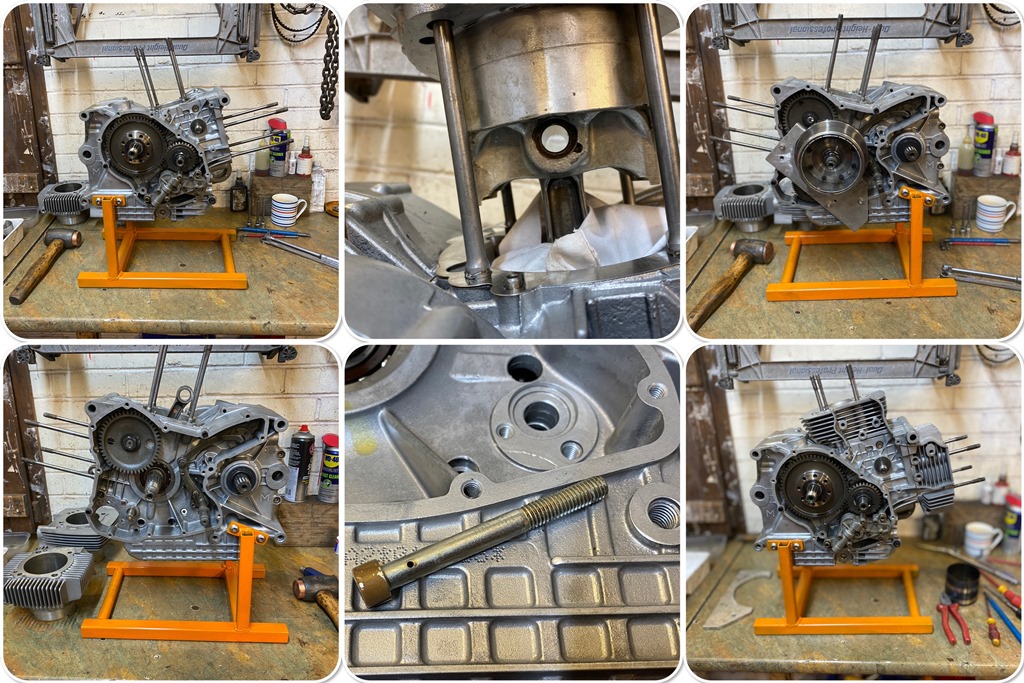

Started the engine build… these are simple engines to build, just a couple of points to remember… There is one special bolt in the crankcase that has an oil feed hole in it. Its also much easier to pop the piston into the bore, and then put the pin in, the rings are very fragile (and expensive!) make sure you have some rag in holes though, those pin circlips have a life of their own! in one of the pictures you can see a plate which holds the flywheel… this is necessary as the alternator nut and crank nut are VERY tight and need torqueing to 190 NM.

I would like to thank the local council for the steel to make the engine stand. Leaving a large sign in the hedge at the side of the road for 2 years, I felt I had to re-cycle it ��