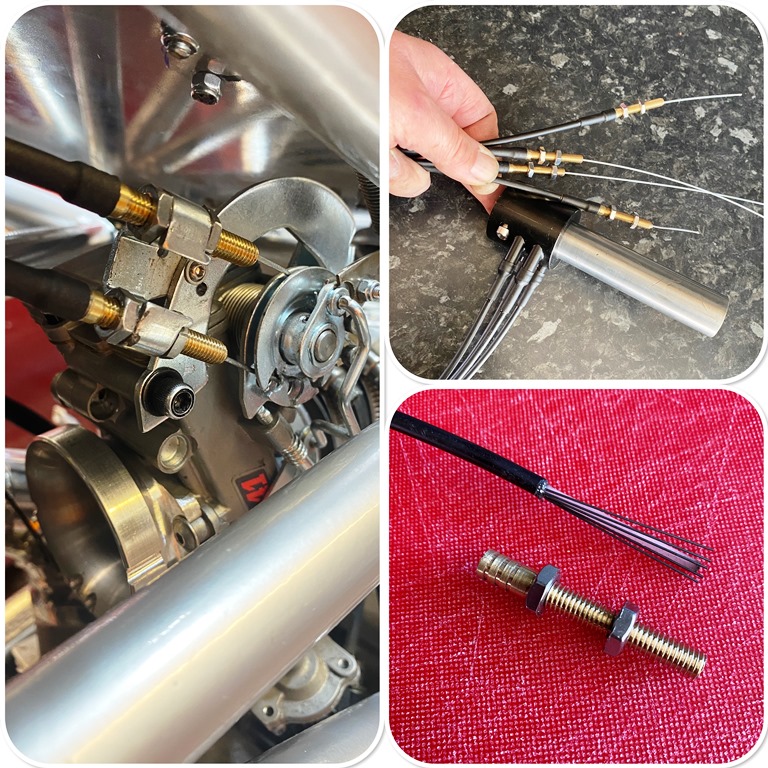

I finished the throttle off... I had to make the adjusters as they needed to be a custom size. I also used cycle gear cable as the nice thing about it is the outer wire is longitudinal, which has several advantages, the one being that you can cut it so the inner liner can extend into the adjusters and into the throttle which makes the entire run of the inner cable within the liner. I was very pleased with the light action, and only a 1/4 of a turn closed to open. We all know a fast action throttle adds 20 BHP ;D

I know that I should use suppressed leads, but I prefer to use copper cored ones. they are easy to make up and you can make them to the spot on length. I have had that crimp tool 50 years!

one of the things I wanted to do was get rid of the rubber frame bungs… so I turned up some alloy ones. I needed some alloy bar, so I popped into my local metal recyclers… he had several skips of alloy round bar and machined square and oblong billets, all different sizes… many marked on the end with the material specification! They were just about to be taken away so I had to be quick, I really had to restrain myself though, it was like Christmas had come early!