The check valves are resilient rubber and cover four 1mm drillings, the application a pressure differential in the correct direction is will cause once the elasticity of the valve is overcome, the valve to lift off of its seat relieving pressure or vacuum from the tank.

When closed, the valves prevent fuel from escaping.

While symmetrical in shape, the valves are not identical, the pressure relief being thicker than the vacuum relief. The valve should be assembled with the notch adjacent to the vent channel

Check Valves

The vent channel is formed between the cap body and top cover plate, a molded rubber gasket seals the channel.

A fuel level sensor is located in the base of the tank and is held in place with a union nut and sealed with an O ring. The sensor assembly is also used as sealed conduit for the pump power leads.

The sensor contains a float that rides on a shaft within the sensors tubular body, a coil of wire is molded into the wall of the tube. The passage of the float within the tube, changes the resistance of the coil, this causes the low fuel light to illuminate when the resistance reaches a predetermined setting.

Fuel Level Sensor

Operational Issues.

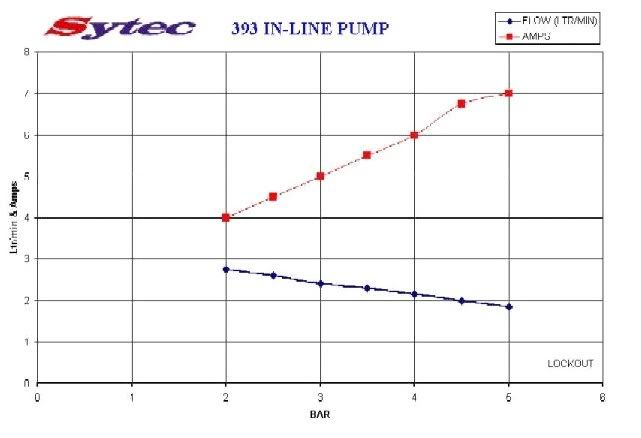

The fuel pump will quite happily run all day at a discharge head of 3bar, at that point the flow is sufficient to conduct the heat away from the pump. The problem comes with the increase in discharge head caused by a blocked filter. Consider the following pump curve (not the Bosch but very similar) (Bosch data is impossible to find).

It can be observed that as the discharge (head) pressure increases the amps increase and the flow decreases. At 5bar the current has risen by 28% and the cooling flow has been reduced by 20%.the heating effect of the additional current is exacerbated by the reduction in flow of coolant, resulting in a general increase in operating temperature, the life of the pump is reduced when operated under these conditions. Regular replacement of the fuel filter is the obvious way to avoid pump failures. Symptoms of a blocked fuel filter would include poor performance at large throttle openings becoming progressively worse and at lower throttle openings.

As the pump is lubricated by the fuel, running it dry will cause irreparable damage. If you run out of fuel, turn off the ignition and don’t turn it on again until you have replenished the tank.

As stated above, voltage is crucial to the pump operation, as the voltage falls so will the pump output, the symptoms being similar to that described for a blocked filter only the degradation in performance being much quicker.

Fuel pressure is also critical to the fueling of the engine, the closer to the design pressure of the 3bar the regulator can control too, the better will be the performance as the ECU assumes the 3bar figure. Ideally an adjustable regulator could be set to maintain the 3 bar design pressure, reducing the production tolerance of the non adjustable OEM unit. Such adjustable regulators are available on the accessories market. Irrespective, there is a band within which